Sheet Metal Peraluman

EN AW 5754

SERVICES

- Possibility of custom coil planishing;

- Possibility of applying PVC.

DOWNLOAD

Sheet Metal Peraluman (EN AW 5754) data sheet

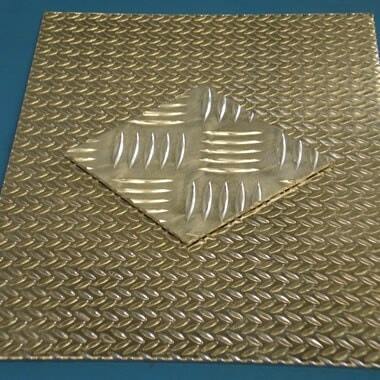

Available in smooth, diamond plate, and rice grain plate formats, this is the most popular alloy for light structural work.

The main alloying element is magnesium, which ensures optimal resistance to corrosion (even in marine environments), excellent mechanical properties, good weldability, and an excellent aptitude for bending.

TECHNICAL CHARACTERISTICS

Weldability: good

Surface treatments

- Technical anodisation: good

- Decorative anodisation: sufficient

Workability: good

Resistance to corrosion

- In normal environments: optimal

- In marine environments: optimal

AVAILABILITY

The sheet metal products in 5754 alloy are available in all commercial formats in the physical state H111 and H32, and in formats with special lengths from coils.

The alloy 5754 is available in smooth format in thicknesses ranging from 1 to 6 mm, and in diamond plate format in thicknesses of 2, 3, and 5mm + Diamond.

GENERAL INFORMATION

Chemical composition (% weight)

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Alu | |

|---|---|---|---|---|---|---|---|---|---|

| Min | 2,60 | ||||||||

| Max | 0,40 | 0,40 | 0,10 | 0,5 | 3,60 | 0,3 | 0,20 | 0,15 | - |

Physical properties

1 MPa = 1 N/mm2 = 0.10197 kg/mm2

- Specific weight (g/cm3): 2.67

- Elastic modulus (MPa): 70000

- Thermal conductivity (W/m °C): 132

- Electrical conductivity at 20°C (m/ Ω mm²): 18

- Thermal expansion coefficient (10 -6/K): 23.8

- Melting range (°C): 590-645

MECHANICAL PROPERTIES

Indicative values

Value (thickness 0.5 ≤ 1.5)

| Tensile strength Rm (N/mm3) | Yield strength Rp 0.2 | Elongation A5 | Hardness HB |

|---|---|---|---|

| 220 | 130 | 8-11 | 63 |

| Physical state | Specific thickness (mm) | Specific thickness (mm) | Rm MPa | Rm MPa | Rp0.2 MPa | Rp0.2 MPa | Min. elasticity (%) | Min. elasticity (%) | Radius of curvature | Radius of curvature | Hardness HBWa |

|---|---|---|---|---|---|---|---|---|---|---|---|

| over | up to | min. | max. | min. | max. | A50 mm | A | 180° | 90° | ||

| 0/H111 | 0.2 | 0.5 | 190 | 240 | 80 | 12 | 0.5 t | 0 t | 52 | ||

| 0/H111 | 0.5 | 1.5 | 190 | 240 | 80 | 14 | 0.5 t | 0.5 t | 52 | ||

| 0/H111 | 1.5 | 3.0 | 190 | 240 | 80 | 16 | 1.0 t | 1.0 t | 52 | ||

| 0/H111 | 3.0 | 6.0 | 190 | 240 | 80 | 18 | 1.0 t | 1.0 t | 52 | ||

| 0/H111 | 6.0 | 12.5 | 190 | 240 | 80 | 18 | 2.0 t | 52 | |||

| 0/H111 | 12.5 | 100.0 | 190 | 240 | 80 | 52 | |||||

| H18 | 0.2 | 0.5 | 290 | 250 | 1 | 88 | |||||

| H18 | 0.5 | 1.5 | 290 | 250 | 2 | 88 | |||||

| H18 | 1.5 | 3.0 | 290 | 250 | 2 | 88 | |||||

| H22/H32 | 0.2 | 0.5 | 220 | 270 | 130 | 7 | 1.5 t | 0.5 t | 63 | ||

| H22/H32 | 0.5 | 1.5 | 220 | 270 | 130 | 8 | 1.5 t | 1.0 t | 63 | ||

| H22/H32 | 1.5 | 3.0 | 220 | 270 | 130 | 10 | 2.0 t | 1.5 t | 63 | ||

| H22/H32 | 3.0 | 6.0 | 220 | 270 | 130 | 11 | 1.5 t | 63 | |||

| H22/H32 | 6.0 | 12.5 | 220 | 270 | 130 | 10 | 2.5 t | 63 | |||

| H22/H32 | 12.5 | 40.0 | 200 | 270 | 130 | 9 | 63 |

Baratè Spa

Via Alberto Baratè, 5

27036 Mortara (PV), Italy

VAT: 00837850189

ER-0248/2021

CONTACT US!